Our Capabilities

We are a PCBA manufacturing service provider offering PCB design, prototyping, assembly, and box build solutions. With advanced equipment and strict quality control, we deliver high-quality, reliable, and efficient electronic manufacturing services to bring your ideas to life.

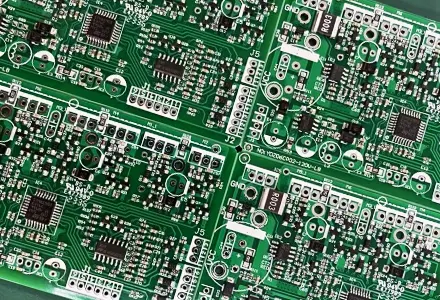

PCBA Assembly

PCBA Assembly mounts electronic components onto PCBs, ensuring precision, reliability, and high performance across various industries. Ensure high quality to customer.

- Layers: 1-42 layers

- PCB Thickness: 0.3MM-4MM

- PCB Size: L*w:50*50–510mm*460mm

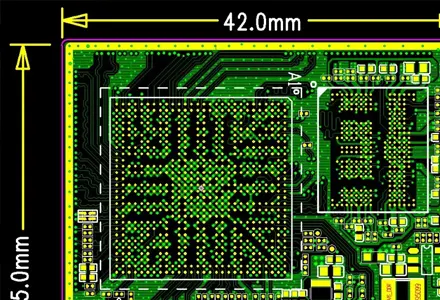

PCB Design

PCB Design is the process of creating circuit layouts that connect electronic components efficiently and reliably. It ensures optimal performance, manufacturability, and product quality for various electronic applications

- Typically Tooling: 30 days

- Typically injection molding: 3 days

- 1 to 1M pcs

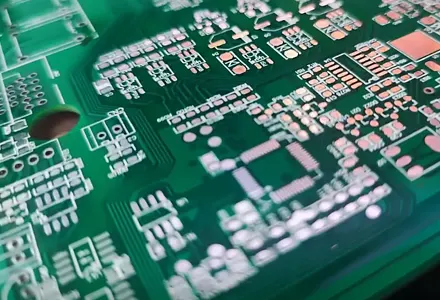

PCB Manufacturing

PCB Manufacturing is the process of producing printed circuit boards that connect and support electronic components. It ensures high precision, durability, and quality for reliable electronic products.

- Typical leading time 3 days.

- Typically +/- 0.15mm or +/-0.006 inch

- State-of-the-Art Technologies

Procurment

Procurement is the process of sourcing and purchasing high-quality electronic components and materials needed for production. It ensures cost efficiency, reliability, and on-time delivery throughout the manufacturing process.

- Tolerances as tight as ±0.2 mm

- Machined parts lead time 1 day

- Max Size: 1400x700x500mm

Box Building

Box Building is the final stage of assembly, integrating PCBs, wiring, and enclosures into a complete, ready-to-use product. It ensures seamless functionality, durability, and professional finishing.

- Wall Thickness 0.8 mm

- Machined parts lead time 4~5 day

- Minimum Possible Batch 1000 pcs

Prototype Assembly

Prototype Assembly is the process of building and testing initial PCB samples to validate design and functionality before mass production. It ensures accuracy, reliability, and faster product development.

- Tolerances as tight as ±0.05 mm

- Wall Thickness 1.5mm~2.5mm

- Quantitites 25 copies per mold

Capabilities Behind Numbers

How to Work With Us

“To begin, simply select a service and upload your .stp file.

Upload files

File's Format

Waiting Feedback

Evaluate

Manufacturing Start

Our Goal

Delivered

Important

About Us

“We are Shenzhen Leadsin Technology Co.Ltd”

PCBase Technology Industry is a comprehensive EMS provider, offering complete end-to-end services—from PCB design and manufacturing to PCBA, product development, component sourcing, SMT/DIP assembly, and final testing.

With a team of experienced engineers and advanced manufacturing capabilities, we deliver reliable and high-quality PCB and PCBA solutions to clients around the world.

Serving industries such as automotive, medical, industrial control, communications, IoT, and consumer electronics, PCBase Technology Industry ensures exceptional quality, strict reliability, and cost-effective solutions for every project.

Application

Our PCBA products are trusted across diverse industries for their superior quality and dependable performance, making them an essential component for many enterprises.

IOT

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Medical

From diagnostic equipment to portable health monitors, our stable, high-reliability assemblies support safe, accurate, and consistent performance in critical healthcare applications.

Security

From access control and alarm systems to smart cameras and sensors, our boards deliver stable, high-performance operation to keep protection systems running around the clock.

Industrial

From automation controllers to power modules and sensor systems, our assemblies ensure stable, long-life performance for factory and field applications.

New Energy

We deliver durable, high-efficiency PCBAs for new energy products, including solar inverters, battery management systems, and EV-related electronics.

Communication

We provide high-performance PCBAs for communication systems, including routers, base stations, wireless modules, and networking equipment.

Blog

Providing you with new insights to help you improve your business

The Functional Failure Analysis Case Study of PCBA Caused by HDI Blink Hole Defects

With the rapid advancement of microelectronics technology, electronic products continue to evolve toward lighter, thinner, shorter, and smaller designs.

Research on Selective Removal and Restoration Processes for Three-Proof Coating Layers on PCBA Electronic Components

Aerospace electronic and electrical equipment continuously faces erosion from special environmental factors such as humid heat, mold, salt spray, and corrosive gases during service.

Optimizing PCB Manufacturing with CCD Back-Drilled Leads

Printed circuit boards (PCBs) provide interconnections for electronic components and parts, forming modules or finished products with specific functions.