Printed Circuit Board Assembly (PCBA) refers to the process of mounting electronic components onto a printed circuit board (PCB).

Industries such as military, aerospace, medical equipment, and automotive electronics utilize high-end precision PCBs.

During assembly, manufacturers impose extremely stringent requirements on the cleanliness of the PCBA surface.

As PCBA dimensions continue to shrink and density increases, the difficulty of removing contaminants also rises, presenting greater challenges for cleaning operations.

PCBA that are not thoroughly cleaned can develop various issues, including parasitic leakage, electrochemical migration, delamination, short circuits, and dendrite growth.

How to swiftly and effectively address contaminants generated during PCBA assembly remains a key focus for the surface mount technology (SMT) industry.

Currently, manufacturers widely use organic solvents to dissolve and extract contaminants.

Among these, the water-based PCBA cleaner VIGON N600 is commonly employed.

When cleaning with VIGON N600, certain PCB solder mask inks react abnormally with it, forming a floating brown substance.

During spray cleaning, this substance easily adheres to the edges and crevices of PCBA, proving difficult to remove.

This can lead to secondary contamination of PCBA, posing a hidden risk of electrical performance failure.

PCBA Cleaning Anomalies

Recently, customer feedback regarding the cleaning of blue solder mask PCBA indicated that the cleaning solution became contaminated during use, resulting in floating brown substances.

However, no such anomalies occurred during the cleaning of green solder mask PCBA.

To determine whether contaminants originate from the PCB or PCBA manufacturing process, engineers designed a validation protocol.

After thoroughly maintaining and cleaning the equipment, they reconstituted the cleaning solution and processed the PCB samples.

The validation steps were: Cleaning Equipment → Drain Old Solution → Maintain Equipment → Prepare New Solution → Clean Unpopulated PCBs → Inspect Solution.

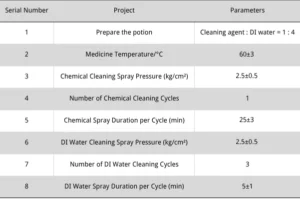

The PCBA cleaning process was confirmed as follows: prepare the solution → load the PCBA → start the equipment → spray the solution → spray deionized water (DI water) → remove the PCBA.

Cleaning parameters are shown in Table 1. Post-cleaning, no abnormalities appeared on green solder mask PCBs.

However, anomalies were detected on blue solder mask PCBs, indicating that the contaminants in the cleaning solution primarily originated from the PCB manufacturing process.

Cleaning Experiment

Production Process Investigation

To investigate how production process parameters affect cleaning agent contamination, engineers fabricated test boards using the following production parameters.

(1) Aluminum Oxide Pretreatment

Ensure scratch depth of 10±3mm, maintain aluminum oxide content at 20±5%, set processing speed to 4.5±0.5m/min, and allow 1 hour of rest after pretreatment completion.

(2) Screen Printing

Employ a 39T mesh screen. Control ink viscosity at 110±20 dPa·s and maintain wet film thickness between 30–50 μm.

Use R brand Model B blue ink. Allow 1 hour of rest after screen printing.

(3) Pre-baking

Set temperature to 75±3°C and duration to 48±3 min. Allow 1 hour of rest after pre-baking.

(4) Exposure and Development

Exposure energy level set to 11. Development solution concentration controlled at 1.0±0.2%, temperature maintained at 30±2°C.

Development upper pressure set to 2.0±0.3 kg/cm², lower pressure to 1.5±0.3 kg/cm², development speed at 5.5 m/min.

After placing components and cleaning the test samples from this batch, engineers observed cleaning agent contamination on the blue solder mask PCBA.

This confirms that the contamination was not caused by abnormal production parameters.

Parameter Optimization Verification

(1) Comparison Test of Exposure Machines, Exposure Energy, and High-Temperature Time

PCBs were produced using R brand Model B blue ink. To evaluate how different conditions affect ink performance, engineers designed a series of comparative tests.

They conducted the tests using both Chinese exposure machines—ORC and DI—while adjusting exposure energy, UV irradiation, and extending high-temperature baking time.

During testing, they used the customer-provided cleaning agent to wipe the ink surface with a lint-free cloth.

The purpose was to observe whether corrosion occurred on the ink and to check for any blue ink residue on the cloth surface.

Detailed test results appear in Table 2.

Test results indicate that after optimizing parameters, corrosion issues occurred in all R-brand Model B blue inks during the cleaning and wiping process on production boards.

Following 12-level exposure energy treatment using a DI exposure machine and extended high-temperature baking time, corrosion in this ink model intensified.

(2) Comparison Test of Post-Development Re-exposure vs. UV Light Exposure

After developing the test boards, engineers cured the ink using two methods: re-exposure and UV light irradiation.

They prepared a cleaning solvent by mixing the customer-supplied cleaner with DI water at a 1:4 ratio.

The test boards were then cleaned using both wiping and immersion methods.

For the immersion method, the test plates were submerged in the cleaning solvent at 60°C for 25 minutes.

Test results showed that no ink dissolution or leaching occurred after either post-development re-exposure or UV irradiation.

However, all test plates exhibited color loss during the wiping test.

Comparative Testing of Different Ink Colors

To investigate the corrosive effects of cleaning solvents on different ink colors, engineers used the same solvent provided by the customer.

They mixed this solvent with deionized water at a 1:4 ratio to prepare the cleaning solution.

Two cleaning methods were then employed.

The first method involved wiping the board surface with a lint-free cloth impregnated with the cleaning agent.

The second method involved immersing the PCB in the cleaning solution at 60°C for 25 minutes.

In the comparative test, immersion caused no ink dissolution for green, bright green, red, black, or white solder mask inks.

Additionally, wiping did not result in any color transfer.

However, while blue solder mask ink showed no dissolution after immersion, color transfer occurred.

The results indicate that only the blue ink is incompatible with the client’s cleaning agent, leading to color transfer and potential contamination of the cleaning solution during the cleaning process.

Blue Ink Comparison Test

(1) Blue Ink Performance Testing

Design test experiments involved immersing blue ink test panels in 10% sulfuric acid (H₂SO₄), 10% sodium hydroxide (NaOH), and 10% isopropyl alcohol solutions.

After soaking for 30 minutes at room temperature, the plates were removed to observe whether ink peeling or color fading occurred on the ink surface.

Test results showed that the blue ink exhibited no peeling or fading after immersion in any of the above solutions, indicating that the ink’s inherent chemical resistance is normal.

(2) Testing of Different Brands of Blue Ink

Test results indicate that under immersion conditions, all four blue solder mask inks exhibited no dissolution.

However, during the wiping process, all inks exhibited color fading.

To investigate the corrosion effects of cleaning solvents on different brands of blue ink, engineers used the customer’s identical solvent.

They mixed this solvent with DI water at a 1:4 ratio to prepare the cleaning solution.

Two cleaning methods were then employed.

The first method involved wiping the PCB surface with a lint-free cloth impregnated with the cleaning agent.

The second method involved immersing the PCB in the cleaning solution at 60°C for 25 minutes.

Test results showed that none of the four blue solder mask inks exhibited dissolution. However, all inks demonstrated color loss during the wiping process.

Comparative testing of different brands of blue ink revealed that all brands exhibited color loss after cleaning with the customer’s solvent.

This indicates poor compatibility between the blue inks and the cleaning agent.

(3) Test of R Brand Model B Blue Ink

The R Brand Model B blue ink consists of phthalocyanine blue pigment, powder, defoamer, resin, and photoinitiator curing mixture.

To identify the component causing brown stratification in the cleaning agent, engineers designed relevant experiments.

They mixed each ink component separately with the cleaning agent, stirred the mixtures, and then allowed them to settle.

This process enabled observation of any substances formed in the cleaning agent solution.

The experimental results are as follows:

①Blue (phthalocyanine blue) pigment and green (cyan) pigment did not react with the cleaning agent.

After 10 minutes of settling, they suspended on the cleaning agent surface, appearing blue and green respectively, with no brown substances formed.

② Various powders did not react with the cleaning agent. After 10 minutes of settling, the powders deposited at the bottom, with no brown substances formed.

③The defoamer did not react with the cleaning agent. After standing for 10 minutes, part of the defoamer floated to the surface while the rest settled at the bottom.

It did not alter the color of the cleaning agent, and no brown substance was produced.

④ When the cured mixture of resin and photoinitiator is mixed with the cleaning agent and left to stand for 10 minutes, the resin is removed and its surface appears pale yellow.

Analysis suggests this may be due to partial resin dissolution. However, no brown substance is produced.

Test results for R brand Model B blue ink indicate that none of its components react with the cleaning agent to form brown substances.

(4) Comparison of R Brand Green Ink and Blue Ink

The formulation components and structures of blue ink and green ink are largely similar. Blue ink utilizes phthalocyanine blue pigment, while green ink employs phthalocyanine green.

During the exposure process, phthalocyanine green absorbs fewer light waves.

This allows greater absorption of the photoinitiator’s light waves, facilitating surface light-curing reactions.

As a result, the coating exhibits superior corrosion resistance.

Phthalocyanine blue exhibits the opposite characteristics. Phthalocyanine green has a molecular weight of 1100, higher than phthalocyanine blue’s 580.

This grants phthalocyanine green superior encapsulation properties when bound by resin, along with enhanced mechanical stability and resistance to chemical attack.

Improvement Measures

Based on the comparison of green and blue ink compositions, it is evident that the ink formulation remains unchanged.

Under these conditions, pigments with higher molecular weight exhibit greater resistance to cleaning agent corrosion.

Therefore, we are committed to sourcing phthalocyanine blue pigments with higher molecular weights to develop and produce blue inks that are less susceptible to dissolution by cleaning solutions.

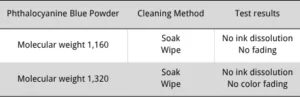

Researchers studied the corrosion resistance of different phthalocyanine blue pigments against cleaning solutions.

They performed comparative tests on two blue solder mask inks containing phthalocyanine blue pigments with molecular weights of 1160 and 1320.

The cleaning solvents were prepared by mixing the customer’s identical solvent with DI water at a 1:4 ratio.

Two cleaning methods were applied: wiping the board surface with a lint-free cloth soaked in the cleaning agent, and immersing the PCB in the solvent at 60°C for 25 minutes.

The test results are shown in Table 3.

Results indicate that the modified blue ink (1160), with a molecular weight similar to phthalocyanine green powder (1100), showed no ink dissolution or leaching after immersion cleaning.

However, color loss occurred during wipe cleaning with the solvent.

The modified blue ink used phthalocyanine blue powder with a molecular weight of 1320, which is higher than the phthalocyanine green powder at 1100.

After immersion cleaning, it showed no ink dissolution or leaching.

Additionally, no color fading was observed after wiping.

Conclusion

This paper analyzes the issue of blue solder mask ink contamination by cleaning agents on PCBA boards, identifies the specific causes of abnormalities, and proposes effective improvement measures.

Research findings indicate that using a modified blue solder mask ink with a molecular weight of 1320 can effectively prevent contamination from the cleaning agent.

This ensures that no residual floating particles remain on the PCBA surface after cleaning.

Other abnormal issues may arise during PCBA surface cleaning processes, requiring case-specific analysis and further investigation into new technologies for resolution.