Surface Mount Technology (SMT) is a critical process technology for secondary integration.

This technology primarily consists of key processes such as solder paste printing, component placement, reflow soldering, and cleaning.

As the initial step in the SMT process, the printing process directly impacts the yield rate of subsequent processes and is a key factor determining the overall defect rate of SMT.

Research indicates that solder paste printing is the primary source of defects in the SMT process, accounting for approximately 70% of the total defect rate.

Challenges in High-Density Solder Paste Printing

As microelectronic products evolve toward high-density integration and miniaturization, low-pitch, small-size solder paste printing processes face significant challenges.

Typical printing defects such as underfill, overfill, offset, and solder spit have become critical factors limiting improvements in product yield.

Although the industry commonly employs Solder Paste Inspection (SPI) systems after printing equipment to evaluate print quality, printing parameters exhibit typical multi-parameter coupling characteristics.

Consequently, selecting optimal printing process parameters often relies on

manually adjusted based on experience, with SPI detection parameters then determined according to the printed paste morphology.

In manufacturing environments characterized by diverse product varieties, small batch sizes, and high reliability requirements, engineering practices face several technical challenges.

These challenges include frequent stencil replacements and continuous solder paste updates.

This not only significantly reduces the efficiency of traditional experience-based parameter adjustment methods but also substantially increases production costs.

Machine Learning–Driven Process Optimization Approach

In recent years, machine learning (ML) technology has achieved remarkable progress, with continuous improvements in model frameworks and theoretical research.

ML technology has demonstrated outstanding performance in system modeling, simulation prediction, and structural optimization, successfully applied across multiple engineering scenarios.

However, the relatively limited feature dimensions and sample data collected from SMT production lines reduce model applicability.

Existing research primarily focuses on constructing printing defect prediction models, with insufficient exploration into the optimal combination of solder paste printing process parameters.

This paper collects printing process and quality parameters from SMT production lines to construct a database.

By training multiple machine learning models, it achieves effective prediction of printing quality.

The Ant Colony Optimization (ACO) algorithm searches for the global optimal solution of printing process parameters, providing an optimization scheme that enhances production yield and efficiency.

Construction of Datasets and Machine Learning Methods

Figure 1 illustrates the technical workflow of this study, primarily encompassing experimental data collection, machine learning modeling, ant colony optimization of process parameters, and data validation.

The specific steps are as follows. First, collect process data from the solder paste printing line.

We construct an experimental dataset through preprocessing steps, including data distribution analysis, missing value handling, and standardization.

Based on feature importance analysis, we identify key process parameters.

We then split the dataset into training and testing sets at an 8:2 ratio.

By comparing the performance of multiple machine learning models, we train each model separately to target specific printing quality metrics.

This process ultimately establishes the printing quality prediction models.

This study also employs the Ant Colony Optimization (ACO) algorithm to search for the optimal combination of process parameters for printing quality.

The algorithm initializes key parameters, such as the number of ants and pheromone evaporation factors.

Based on heuristic information, it guides the path search and dynamically updates pheromone concentration to obtain high-quality solutions.

The iterative process continues until termination conditions are met, ultimately outputting the optimal parameter combination.

Finally, we validate the printing quality of the optimal process parameter combination on the SMT production line.

Solder Paste Printing and Data Collection

1. Experimental Setup and Printing Equipment

The industry commonly uses stencil thicknesses of 0.08–0.12 mm.

To investigate solder paste printing parameter optimization, this study fixed the stencil thickness at 0.1 mm and selected the 0402 component pad—sensitive to printing parameters—as the research subject.

The automated printing equipment used was Kaige Precision’s GKG-G5.

Based on solder paste printing principles, we set four key process parameters on the fully automatic printing machine.

These parameters are squeegee pressure (1–10 kg), printing speed (10–500 mm/s), stencil gap (0.1–10 mm), and demolding speed (0.1–10 mm/s).

Simultaneously, a 3D SPI system captured the printed relative area, height, and relative volume of the solder paste.

We compare these measurements against the target values (125% relative area, 87% relative height, 115% relative volume) to evaluate print quality.

2. Data Acquisition and Sample Collection

Through the production line data acquisition system, we obtain real-time equipment information to construct a printing dataset.

From this dataset, we randomly select 200 data sets as the sample collection.

3. Data Distribution and Quality Analysis

Figure 2(a) displays the distribution of printing quality data, with the main diagonal showing histograms of target variables alongside Kernel Density Estimation (KDE) curves.

The continuity of the KDE curve effectively captures the distribution characteristics of the data.

Peaks indicate high-density regions in the dataset, while troughs represent sparse areas.

Combined with the histogram, we determine the kurtosis coefficients of the solder paste printing sample quality data to be 3.32, 4.70, and 2.92, respectively.

These values indicate a normal distribution, considering that a normal distribution has a kurtosis coefficient of 3.

To observe linear relationships between variables, we add a linear fit curve (red) and a 90% confidence interval (blue banded area).

Results indicate a significant linear relationship between relative solder paste printing area and relative volume, while the linear relationships between relative height and relative area/volume are weaker.

As shown in Figure 2(b), the data for squeegee pressure, printing speed, and demolding speed exhibit a right-skewed bimodal distribution with moderate to low kurtosis.

The distribution of screen gap exhibits left skewness (skewness = −0.75) and a peaked shape (kurtosis = 3.22), indicating pronounced asymmetry and central tendency.

Data quality checks reveal 100% completeness, with only 0.5% outliers detected by the Tong 3 criterion.

These high-quality distribution characteristics provide a reliable foundation for training and validating machine learning models.

Predictive Model for Solder Paste Printing Quality and Process Parameter Optimization

1. Feature Correlation and Process Parameter Analysis

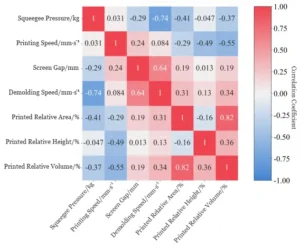

Figure 3 illustrates the importance of features using Pearson correlation coefficients, with values ranging from −1 to 1 representing negative and positive correlations, respectively.

The target printed relative area exhibits a strong positive correlation with the target printed relative volume (r = 0.82).

This indicates that solder paste volume increases synchronously with printing area expansion, which is consistent with the linear fitting curve shown in Figure 2(a).

Squeegee pressure exhibits a strong negative correlation with release speed (r = −0.74).

Higher squeegee pressure enhances adhesion or friction between solder paste and stencil aperture walls, significantly increasing interfacial bonding force.

This increased adhesion directly elevates shear resistance during release.

To ensure complete solder paste transfer and prevent defects such as tailing or bridging, we should appropriately reduce the release speed.

This provides sufficient separation time and minimizes shear stress, enabling a stable release process.

Screen gap exhibits a moderate positive correlation with release speed ( r= 0.64).

As the distance between the stencil and PCB, screen gap directly influences the residual solder paste on the PCB after printing.

When the stencil gap increases, the contact area between the solder paste and the stencil aperture walls expands.

This expansion leads to enhanced interfacial adhesion and significantly increased release resistance.

To facilitate complete solder paste transfer, we must appropriately increase the release speed.

Therefore, in practical processes, optimizing the complex coupling relationship among squeegee pressure, stencil gap, and release speed is a crucial approach to improving solder paste printing quality.

2. Machine Learning Models for Solder Paste Quality Prediction

This study employs a variety of machine learning models for comparative analysis, with Multiple Linear Regression (MLR) and Huber Regression serving as baseline models .

We use MLR to establish a linear relationship reference, while we adopt Huber Regression for its robustness to outliers.

Support Vector Machine (SVM) demonstrates significant advantages in handling high-dimensional nonlinear problems.

K-Nearest Neighbors (KNN) and Multilayer Perceptron (MLP) possess unique capabilities in local feature modeling and complex nonlinear mapping, respectively;

Random Forest (RF) and Decision Tree (DT) excel in feature importance analysis and model interpretability, providing an interpretability dimension for model comparison.

This diversified model selection strategy ensures comprehensive coverage of both linear and nonlinear modeling approaches.

It also provides multi-faceted modeling solutions for optimizing solder paste printing process parameters through systematic comparative analysis.

This approach balances predictive accuracy, robustness, and interpretability.

Solder paste quality prediction falls under regression tasks.

We commonly evaluate it using metrics such as Mean Absolute Error (MAE), Root Mean Square Error (RMSE), and the Coefficient of Determination (R²).

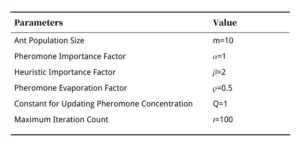

3. Ant Colony Optimization for Process Parameter Optimization

The Ant Colony Optimization (ACO) algorithm is a swarm intelligence optimization technique inspired by the foraging behavior of ants in nature.

It simulates the pheromone release and collaborative optimization mechanisms of ant colonies during search processes.

By leveraging positive feedback and distributed computing principles, it effectively explores high-dimensional solution spaces and approximates global optimal solutions.

For optimizing the solder paste printing process parameters, the ACO constructs a parameter solution space that includes squeegee pressure, printing speed, stencil gap, and de-molding speed.

It then simulates ants’ search within this parameter space.

Each ant represents a candidate parameter combination and follows pheromone concentration and heuristic information to converge toward the optimal parameter region.

The algorithm’s distributed nature enables effective handling of complex parameter coupling relationships, while its adaptive mechanism ensures robustness under dynamic process conditions.

Initialization parameters for the ant colony optimization algorithm are shown in Table 1.

Model Results Analysis and Experimental Validation

Analysis of Solder Paste Quality Model Results

1. Dataset Preparation and Model Training

The collected dataset was randomly split into training and testing sets at an 8:2 ratio for training and testing the solder paste printing quality prediction model.

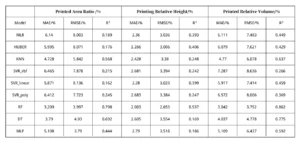

Simultaneously, experiments compared the performance of MLR, HUBER, KNN, SVM with radial basis kernel functions (RBF, linear, poly), RF, DT, and MLP.

During training, 10-fold cross-validation was employed for model parameter optimization.

We train the model separately for each of the three printing quality parameters to identify the parameters that yield optimal model generalization capability.

2. Model Performance Evaluation

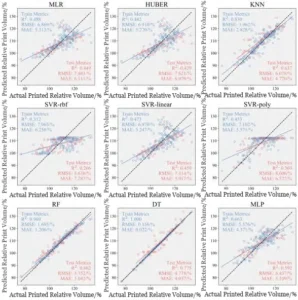

The results are shown in Table 2. Taking the prediction of relative printed volume by different models as an example, the scatter plots and fitted curves are shown in Figure 4.

As indicated in Table 2, except for the Random Forest and Decision Tree models, all other models have a coefficient of determination below 0.5 on the relative printed area test set.

This indicates underfitting.

The decision tree model performed best on the relative printed area training set (R² = 0.999, RMSE = 0.225%, MAE = 0.032%), but its performance on the test set was poor, exhibiting severe overfitting (R² = 0.692, RMSE=3.997%, MAE=3.209%).

The random forest model performed well on both the relative printed area training and test sets, achieving a test set coefficient of determination of 0.789.

As shown in Figure 4, the random forest model excelled in predicting the relative printed area.

It also achieved the best fit on the relative printed volume test set, with a coefficient of determination of 0.862.

3. Feature Importance and Prediction Limitations

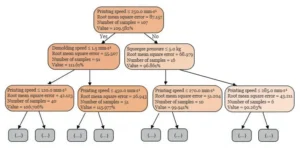

Figure 5 displays the node visualization results of the Random Forest model when predicting the target relative printed volume.

Printing speed appears as the root node, indicating its highest importance within the model.

This aligns with the Pearson correlation analysis results in Figure 3, where printing speed exhibits a significant negative correlation (r = −0.55) with target relative printed volume.

The negative correlation between printing speed and relative volume/area arises primarily because higher speeds reduce solder paste dwell time at stencil apertures, leading to incomplete transfer.

Given solder paste’s thixotropic properties, rapid squeegeeing generates shear forces that alter rheological stress and diminish flowability.

These factors collectively explain the negative relationship between printing speed and relative printing metrics.

In the prediction task for relative printing height, the coefficient of determination for all models was below 0.6, indicating a weak correlation between printing height and key process parameters.

We primarily attribute this low prediction accuracy to the following factors.

Printing height exhibits low sensitivity to process parameters and likely depends mainly on the inherent characteristics of the solder paste, such as viscosity, thixotropy, and rheological behavior.

Experimental Validation of Solder Paste Printing Quality

1. Optimization of Printing Process Parameters Using ACO

To meet the expected printing quality targets (relative area 125%, relative height 87%, and relative volume 115%), we combine the Ant Colony Optimization (ACO) algorithm with a Random Forest model.

This approach enables the prediction of optimized printing process parameters that closely approach these quality goals, demonstrating the robustness of the algorithmic workflow.

As an heuristic algorithm, the ant colony algorithm inherently possesses a degree of randomness.

Therefore, by integrating the ant colony algorithm with machine learning, we generate five batches of optimal printing process parameter combinations, each comprising 20 sets.

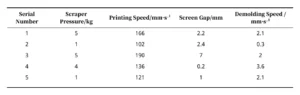

Considering safety and machine performance factors, the final selected optimal printing process parameter combinations are shown in Table 3.

Predictions were made in ascending order, with printing quality decreasing sequentially.

2. Experimental Validation of Optimized Parameters

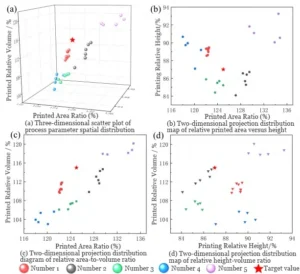

As shown in Figure 6, we conduct 5 to 8 experiments for each of the 5 sets of process parameters, collecting a total of 29 sets of printing quality parameters.

All results were close to the target values (red stars).

The first set of process parameters yielded the best printing quality indicators—128.39%, 86.56%, and 113.09%—with relative errors of 2.71%, 0.51%, and 1.66%, respectively.

3. Analysis of Printing Quality Results and Algorithm Performance

The fifth set exhibited the largest deviation. Although higher printing speeds typically reduce solder paste volume, the smaller stencil gap in this set significantly and negatively impacted paste volume.

This led to increased paste accumulation, exacerbated by the relatively fast demolding speed.

Consequently, the fifth set’s printed relative area, height, and volume all exceeded those of the second set under identical squeegee pressure.

Experimental results demonstrate that the Ant Colony Optimization algorithm exhibits outstanding global search capabilities and convergence efficiency.

It effectively optimizes solder paste printing process parameters, providing a reliable solution for complex process optimization challenges.

Conclusion

This study proposes an SMT solder paste printing process parameter optimization method based on machine learning and ant colony optimization.

Analysis of 200 sets of production line data revealed that printing quality metrics follow a normal distribution.

Significant negative correlations were observed between squeegee pressure and demolding speed (r = −0.74), and between printing speed and relative printing area, relative height, and relative volume (r = −0.29, −0.49, −0.55).

Comparative analysis of nine machine learning models revealed that the Random Forest model achieved optimal performance in predicting relative printing area, relative height, and relative volume (R²=0.798, 0.537, 0.862).

The lower prediction accuracy for relative height was primarily attributed to insufficient sensitivity of process parameters and inherent characteristics of the solder paste.

The Ant Colony Optimization algorithm produced the optimal process parameter combination: squeegee pressure 5 kg, printing speed 166 mm/s, stencil gap 2.2 mm, and demolding speed 2.1 mm/s.

This combination demonstrated outstanding performance in practical validation.

The corresponding printing quality metrics—relative area 128.39%, relative height 86.56%, and relative volume 113.09%—closely matched the target values.

This study provides a novel approach for optimizing complex processes, offering significant engineering application value.