Printed circuit boards (PCBs), born in the 1940s, have seen the development of numerous distinct types over more than seventy years since their commercialization in the 1950s.

Different PCBs exhibit distinct advantages based on variations in substrate materials, number of conductor layers, and structural configurations, catering to diverse electronic device applications.

To facilitate better differentiation, classification, and naming are essential.

PCB classification methods generally fall into three categories: classification by application, classification by substrate material, and classification by structure.

Classification by Application

Classification by application refers to the type of electronic device or apparatus in which the PCB is used, such as radio boards, television boards, computer boards, mobile phone boards, automotive boards, etc.

The emergence of any new electronic device necessitates a corresponding new PCB.

Today, virtually all electronic and even electrical equipment incorporates PCBs, resulting in an ever-growing, countless variety of PCBs named according to their application devices.

The classification of PCBs by application, from broad categories down to specific devices, is illustrated in Figure 1.

Previously, PCBs were broadly categorized as consumer (civilian) PCBs, industrial (equipment) PCBs, and military PCBs.

However, modern electronic devices are far more complex than before, with a single device capable of application across multiple domains.

Consequently, clear differentiation by application has become challenging.

For instance, a mobile phone serves both as a personal item and a business communication tool; automobiles include private vehicles, official vehicles, and military vehicles.

Products within the same category often have multiple uses, making the classification in Figure 1 rather broad and frequently overlapping.

While categorizing PCBs by application provides a clear, intuitive view of product purpose, modern complex electronic devices require multiple types of PCBs.

For instance, automotive PCBs encompass rigid boards, flexible boards, single-sided boards, and multilayer boards.

Simply labeling a PCB as “automotive PCB” does not indicate its performance level. Categorization by application offers a general understanding of the reliability level required for the PCB.

Classification by Base Material

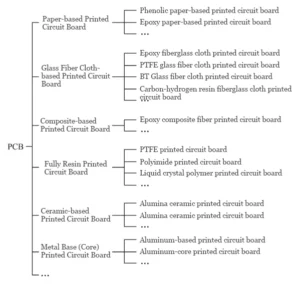

Classification by base material refers to naming the PCB after the substrate material used, as shown in Figure 2.

Some PCBs are directly designated by their base material specification codes, such as FR-2 PCB and FR-4 PCB.

The advantage of this classification is that it identifies the type of base material used in the PCB, revealing the product’s fundamental performance characteristics.

However, the same substrate material can be used to manufacture PCBs with different structural types and applications.

For example, epoxy glass cloth-based material (FR-4) is used in single-sided, double-sided, and multilayer boards.

Today, substrate materials are subdivided into hundreds of varieties, and even within the same broad category, numerous specifications and models exist with significantly different performance characteristics.

Classification by Structure

Classification by structure refers to categorizing PCBs based on structural strength, which can be divided into rigid boards, flexible boards, and rigid-flex boards.

These are further subdivided by the number of conductor layers into single-sided boards, double-sided boards, and multilayer boards, as shown in Figure 3.

The structural characteristics of PCB products more accurately reflect their performance features and practical value.

For instance, rigid boards are suitable for component mounting, while flexible boards can be bent for three-dimensional installations.

Single-sided boards are relatively simple and cost-effective, whereas multilayer boards are comparatively complex.

Consequently, the industry predominantly classifies PCB types based on their structural characteristics.

Additionally, there are PCB types classified by manufacturing processes, such as multilayer boards (multi-layer PCBs formed by directly laying metal conductors on an insulating substrate) and laminated multilayer boards (multi-layer PCBs achieving high-density interconnections through layer-by-layer stacking).

There is also classification based on the combination of PCB substrate materials and structure, such as single-sided phenolic paper PCB, double-sided epoxy glass cloth PCB, multilayer polyimide (PI) PCB, polyimide flexible single-sided PCB, polyester (PET) flexible single-sided PCB, etc.

This classification provides an intuitive and clear representation of product performance characteristics, though the lengthy names can appear cumbersome.